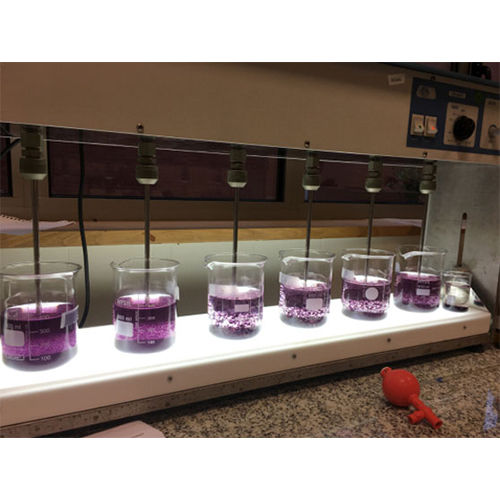

Boiler water chemicals

Price 350.0 INR/ Unit

Boiler water chemicals Specification

- Physical Form

- Solid

- Grade

- Industrial Grade

- Type

- Boiler water chemicals

- Application

- Drinking Water Treatment

Boiler water chemicals Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- Karnataka, Kerala, Andhra Pradesh, Tamil Nadu, Telangana

About Boiler water chemicals

- Scale And Corrosion Control

- Scale Conditioner

- Dispersants

- Condensate Line Corrosion Control

- Oxygen Scavenger

During water treatment pH adjustments may also be required The pH is brought up or down by adding basics or acids An example of lowering the pH is the addition of hydrogen chloride in the case of a basic liquid.

Certain water treatment chemicals phosphates for example if added incorrectly could also precipitate and add to this scaling problem To avoid such situations consideration should be given to the use of polymerbased boiler water sludge conditioners to prevent the suspended solids from settling and baking onto important boiler system surfaces Polymer conditioners keep the unwanted matter sludge in solution which can then be removed via the boiler blowdown.

Specification

|

Usage/Application |

Water Treatment Plant |

|

Type Of chemicals |

Corrosion Inhibitor |

|

Packaging Size |

50-100 L |

|

Ph Value |

7 |

|

Storage Temp |

-18 to 25 degree C |

|

Shelf Life |

1 Year |

|

Physical State |

Liquid |

|

Brand |

Thermax |

|

Packaging Type |

Plastic Can, HDPE Drum |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in WATER TREATMENT CHEMICALS Category

Cooling Water Chemicals

Price 300.0 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Cooling Water Chemicals

Grade : Industrial Grade

Application : Drinking Water Treatment

Physical Form : Solid

Ion Exchange Resin

Price 150 INR / Kilograms

Minimum Order Quantity : 1 Unit

Type : Other

Grade : Industrial Grade

Application : Drinking Water Treatment

RO water chemicals

Price 300.0 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Other, Water Chemical

Grade : Industrial Grade

Application : Drinking Water Treatment

Physical Form : Solid

Polyelectrolytes Chemicals

Price 250.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Type : Other, Polyelectrolytes

Grade : Industrial Grade

Application : Drinking Water Treatment

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese