Call us: 08045479410

Polyelectrolytes Chemicals

Product Details:

- Grade Industrial Grade

- Type Polyelectrolytes

- Application Drinking Water Treatment

- Click to View more

X

Polyelectrolytes Chemicals Price And Quantity

- 1 Unit

Polyelectrolytes Chemicals Product Specifications

- Drinking Water Treatment

- Polyelectrolytes

- Industrial Grade

Polyelectrolytes Chemicals Trade Information

- 10 Unit Per Month

- 30 Days

- Karnataka Kerala Andhra Pradesh Tamil Nadu Telangana

Product Description

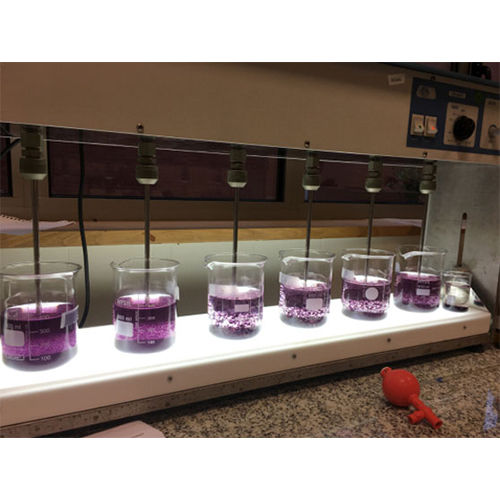

Polyelectrolyte Chemicals

- Raw Water Clarification

- Effluent Treatment

- Colour Removal

- Range Of Process Applications

Thermochem supplies a range of Thermax polyelectrolytes for raw water clarification effluent treatment colour removal and a range of process applications.

Polyelectrolytes are watersoluble polymers carrying ionic charge along the polymer chain Depending upon the charge these polymers are anionic or cationic Polyelectrolytes are available in a wide range of molecular weights and charge densities Homo polymers of acrylamide are also included in the family of polyelectrolytes though they do not carry any charge These are called nonionic Polyelectrolytes have got a wide range of applications right from water purification oil recovery colour removal paper making mineral processing etc Polyelectrolytes are both flocculants as well as de flocculants depending upon the molecular weight A flocculant is essentially a solid liquid separating agent while a de flocculant is a dispersing agent.

Product Benefits

- Effectively precipitates the dye colouring matter in the effluent or dye bath

- Separates and settle the dyes

- Decolorizes the effluent

- Improves the clarity to the treated water

Application Areas

- Colour removal From textile Effluents Industrial Effluents

- Pulp and Paper Dewatering Effluent decolorizing

- Waste Water Activated sludge dewatering

- Textile Sedimentation of wool washing

- Dyes Decolorizing effluent

- Oil Refineries Dewatering of Sludge

- Steel Suspended Solids From BOF

- Hot Strip Mills Oil water Separation

- Leather Dye Effluent treatmen

Efficient Microbes

New technologies are being produced to assist in treating wastewaters conforming to strict environmental regulations One of these new technologies being proposed is the use of efficient microorganisms EM EM technology involves growing applying managing and reestablishing high populations of beneficial organisms in an environment or system Effective microorganism technology has broadened in the last two decades from agriculture to water treatment odor control animal husbandry human health and other numerous industrial treatments This technology is not unique to anyone and is available with many technology partners across the globe which makes it more sustainable in the future.

EM technology may help mitigate the water crisis by removing impurities from wastewater for recycling EM acts to purify wastewater by devouring all of its toxins and eliminating the stench of solid waste almost immediately EM also can absorb toxic gases for example hydrogen sulphide and ammonia and convert them into organic acids thereby eliminating their foul odor EM also has been successfully tested in coloured effluents and was found that it was able to reduce the colour more efficiently and consistently.

How does it work

The basis for using these EM species of microorganisms is that they secrete enzymes antioxidants and metallic chelates The creation of an antioxidant environment by EM assists in enhancing the solidliquid separation which is the foundation for cleaning water One of the major benefits of the use of EM is the reduction in sludge volume Theoretically the beneficial organisms in EM should decompose the organic matter by converting it to carbon dioxide CO2 and methane CH4 while using it for growth and reproduction Studies have suggested this is the case for wastewater treatment plants and septic tanks Introducing EM into the anaerobic treatment facilities helps reduce the unpleasant byproducts of this decomposition and reduces the production of residual sludge These factors suggest that theoretically EM should assist in wastewater treatment by improving the quality of water discharged and reducing the volume of sewage sludge produced.

Well its very simple to put up how technology works The most challenging part is implementing and sustaining this EM technology and an even more crucial challenge is selecting the CORRECT BREED OF MICROBES The current market trend involves using a set of READY MADE MICROBESENZYMES and trying to make some site trails with the same This is where the technology fails The right approach is to breed the microbes based on Effluent and then try to work with the Effluent as the entire basis of this technology is letting the microbes grow and sustain in an environment suitable for it and EVERY WASTE WATER IS DIFFERENT even though the industry type might be the same.

Thankfully Thermax Chemical Divisions complex Biotechnology Lab highly talented scientists have more than enough expertise to select and breed the right microbes We are sure this technology can help many industries treat their Effluent in a more efficient environmentally friendly manner reduce the dependency on powerintensive treatment methods and avoid inorganic chemicals.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese